This is “Product Cost Flows in a Process Costing System”, section 4.2 from the book Accounting for Managers (v. 1.0). For details on it (including licensing), click here.

For more information on the source of this book, or why it is available for free, please see the project's home page. You can browse or download additional books there. To download a .zip file containing this book to use offline, simply click here.

4.2 Product Cost Flows in a Process Costing System

Learning Objective

- Identify how product costs flow through accounts using process costing.

As products physically move through the production process, the product costs associated with these products move through several important accounts as shown back in Figure 4.1 "A Comparison of Cost Flows for Job Costing and Process Costing". In this section, we present a detailed look at how product costs flow through accounts using a process costing system. Later in the chapter, we explain how dollar amounts are established for product costs that flow through the accounts. As you review each of the following cost flows for a process costing system, remember that product costs are now tracked by department rather than by job.

Direct Materials

Question: In a process costing setting, direct materials are often used by several production departments. How do we record direct materials costs for each production department?

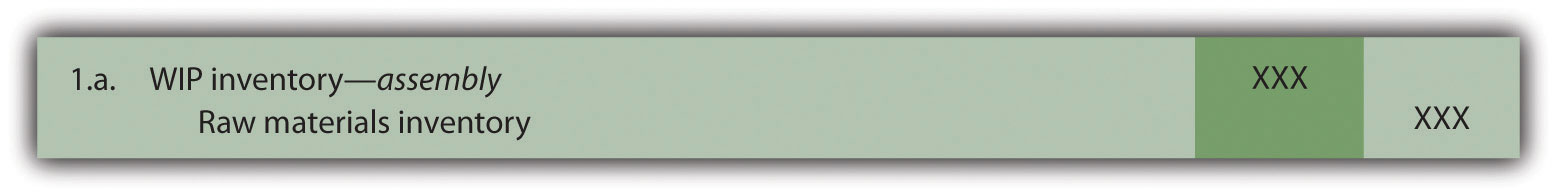

Answer: When direct materials are requisitioned from the raw materials storeroom, a journal entry is made to reduce the raw materials inventory account and increase the appropriate work-in-process inventory account. For example, assume the Assembly department of Desk Products, Inc., requisitions direct materials to be used in production. The journal entry to reflect this is as follows:

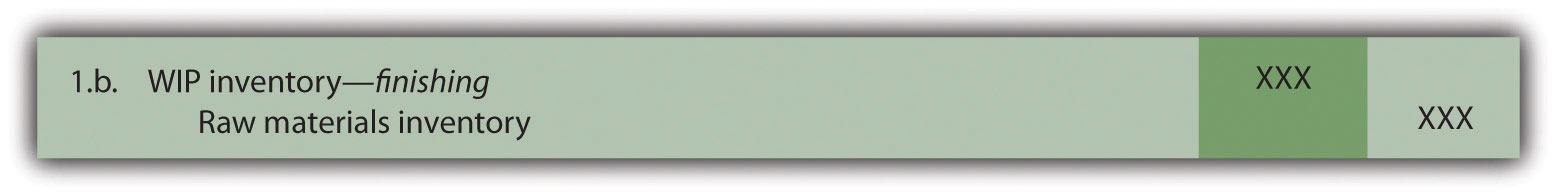

The use of direct materials is not limited to one production department. Suppose the Finishing department requisitions direct materials for production. The journal entry to reflect this is as follows:

Notice that two different work-in-process inventory accounts are used to track production costs—one for each department.

Direct Labor

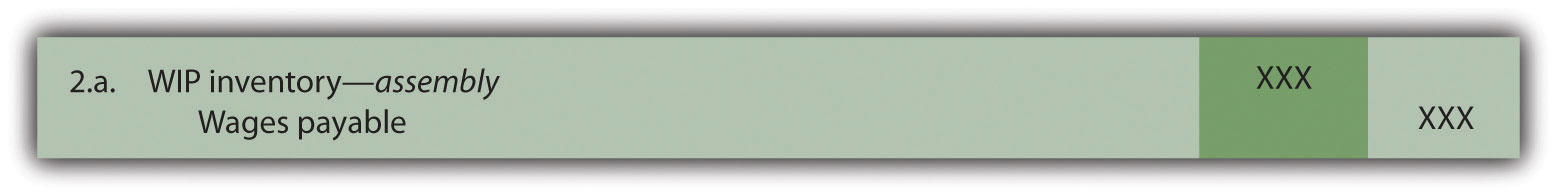

Question: Each production department typically has a direct labor work force. How do we record direct labor costs for each production department?

Answer: Direct labor costs are recorded directly in the production department’s work-in-process inventory account. Assume direct labor costs are incurred by the Assembly department. The journal entry to reflect this is as follows:

As with direct materials, the use of direct labor is not limited to one production department. Suppose direct labor costs are incurred by the Finishing department. The journal entry to reflect this is as follows:

Manufacturing Overhead

Question: Manufacturing overhead costs are typically assigned to products using a predetermined overhead rate using a normal costing system as discussed in Chapter 2 "How Is Job Costing Used to Track Production Costs?" (job costing) and Chapter 3 "How Does an Organization Use Activity-Based Costing to Allocate Overhead Costs?" (activity-based costing). How do we record manufacturing overhead costs for each department?

Answer: Assume manufacturing overhead costs (often simply called overhead costs) are being applied to products going through the Assembly department. The journal entry to reflect this is as follows:

The journal entry to reflect manufacturing overhead costs being applied to products going through the Finishing department is as follows:

Transferred-In Costs

Question: At this point, we have discussed how to record product costs (direct materials, direct labor, and manufacturing overhead) related to each production department. As you review Figure 4.1 "A Comparison of Cost Flows for Job Costing and Process Costing", notice that products often flow from one production department to the next. Transferred-in costsCosts associated with products moving from one department to another. are the costs associated with products moving from one department to another. How do we record transferred-in costs for each department?

Answer: Assume the Assembly department at Desk Products, Inc., completes a batch of desks and moves the desks to the Finishing department. The costs associated with these desks must be transferred from the work-in-process inventory account for the Assembly department to the work-in-process inventory account for the Finishing department. Thus these costs are being transferred in to the Finishing department. The journal entry to reflect this is as follows:

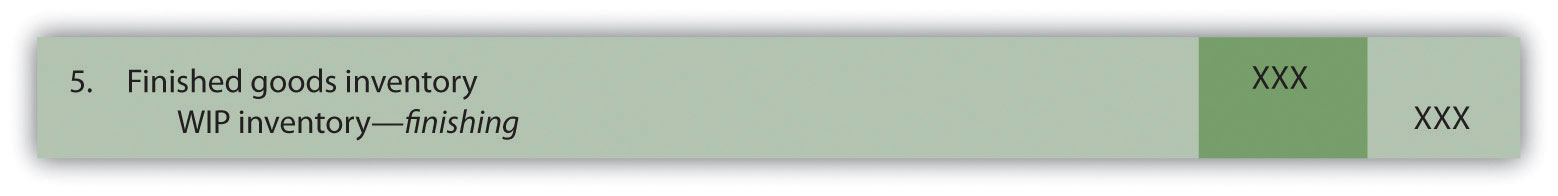

Finished Goods

Question: Goods are completed and ready to sell once they have gone through the final production department. The final production department at Desk Products, Inc., is the Finishing department. How do we record production costs for products moved from the final production department to the finished goods warehouse?

Answer: When goods go through the final production department and are completed, the related costs are moved to the finished goods inventory account. The journal entry to reflect this is as follows:

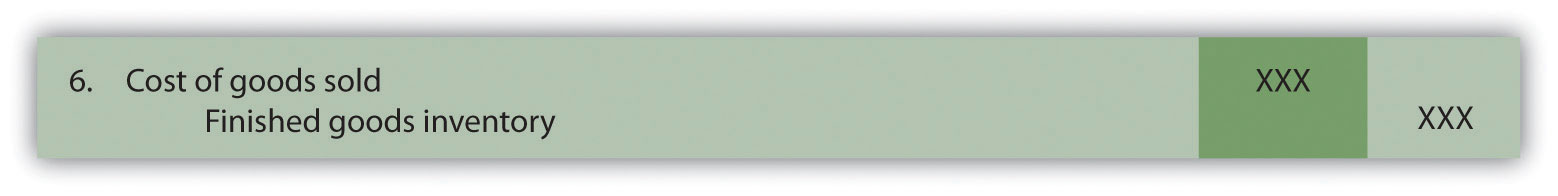

Cost of Goods Sold

Question: How do we record production costs for goods that have been sold?

Answer: Once the completed goods are sold, the related costs are moved out of the finished goods inventory account and into the cost of goods sold account. The journal entry to reflect this is as follows:

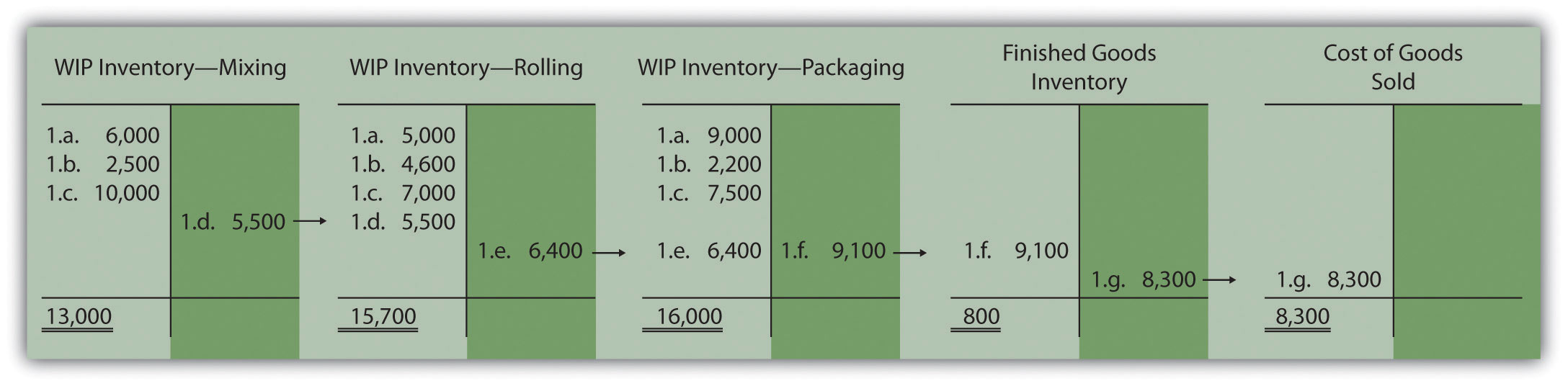

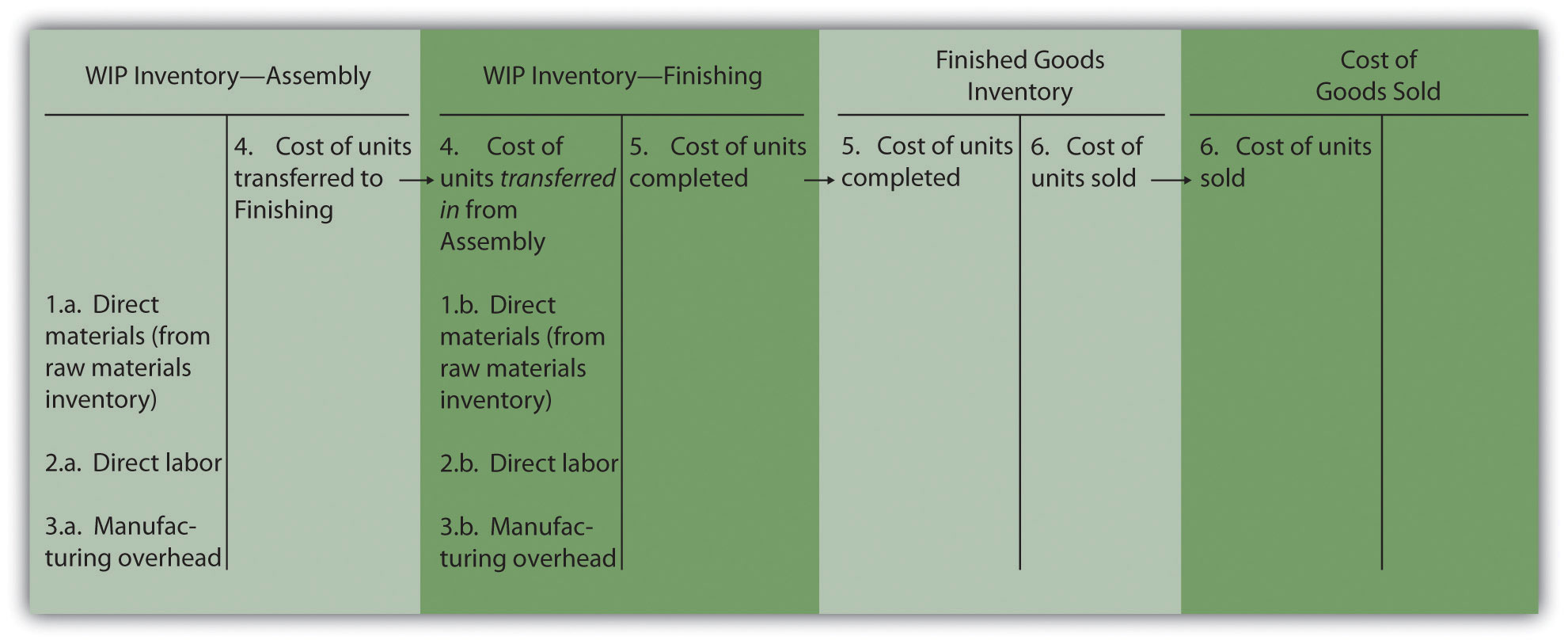

Figure 4.2 "Flow of Product Costs in a Process Costing System" summarizes the flow of product costs through T-accounts for each of the journal entries presented in this section. Note that when goods are sold and production costs are moved from finished goods inventory to cost of goods sold, an additional entry is made to record the revenue associated with this transaction. We do not show this entry because the focus of this section is on the flow of production costs rather than revenues.

Figure 4.2 Flow of Product Costs in a Process Costing System

Business in Action 4.2

Source: Photo courtesy of Mykl Roventine, http://www.flickr.com/photos/myklroventine/3471836813/.

The Production Process for Wrigley’s Gum

The Wrigley Company has 14 factories located in various parts of the world, including North America, Europe, Africa, India, and the Asia/Pacific region. The gum produced by these factories is sold in 150 countries. According to Wrigley Company, 50 percent of Americans chew gum, and on average, each person consumes 190 sticks per year. The number drops to 130 sticks per person in the United Kingdom and to 100 sticks per person in Taiwan.

The production process at Wrigley involves six sequential stages:

- Melting. The gum base, which comes in small round balls, is melted and purified.

- Mixing. The melted base is poured into a mixer, to which sweeteners and flavors are added.

- Rolling. A large “loaf” of gum is sent through a series of rollers, thereby reducing thickness to the desired size.

- Scoring. The gum is cut into the shape of sticks or pellets.

- Conditioning. The gum is cooled and “conditioned” to ensure the right consistency before being packaged.

- Packaging. The gum is packaged and made ready for shipping.

Because Wrigley produces identical units of product in batches employing a consistent process, it likely uses a process costing system. With such a system, Wrigley would need a separate work-in-process inventory account to track costs for each stage of the production process.

Source: Wrigley’s, “Home Page,” http://www.wrigley.com.

Key Takeaway

- The cost flows in a process costing system are similar to the cost flows in a job costing system. The primary difference between the two costing methods is that a process costing system assigns product costs—direct materials, direct labor, and manufacturing overhead—to each production department (or process) rather than to each job. Each production department has its own work-in-process inventory account when using process costing.

Review Problem 4.2

Chewy Gum Corporation produces bubble gum in large batches and uses a process costing system. Three departments—Mixing, Rolling, and Packaging—are involved in the production process. Chewy Gum has the following transactions:

- Direct materials totaling $20,000—$6,000 for the Mixing department, $5,000 for the Rolling department, and $9,000 for the Packaging department—are requisitioned and placed in production.

-

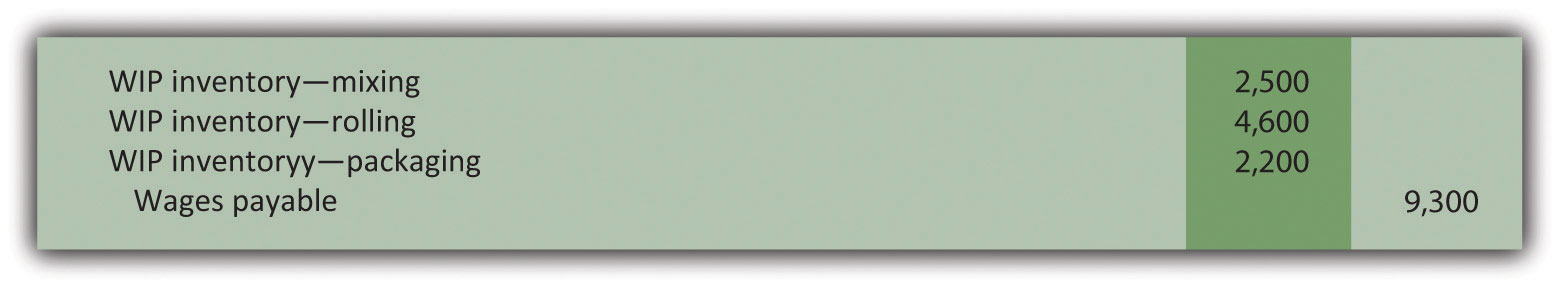

Each production department incurs the following direct labor costs (wages payable):

Mixing $2,500 Rolling $4,600 Packaging $2,200 -

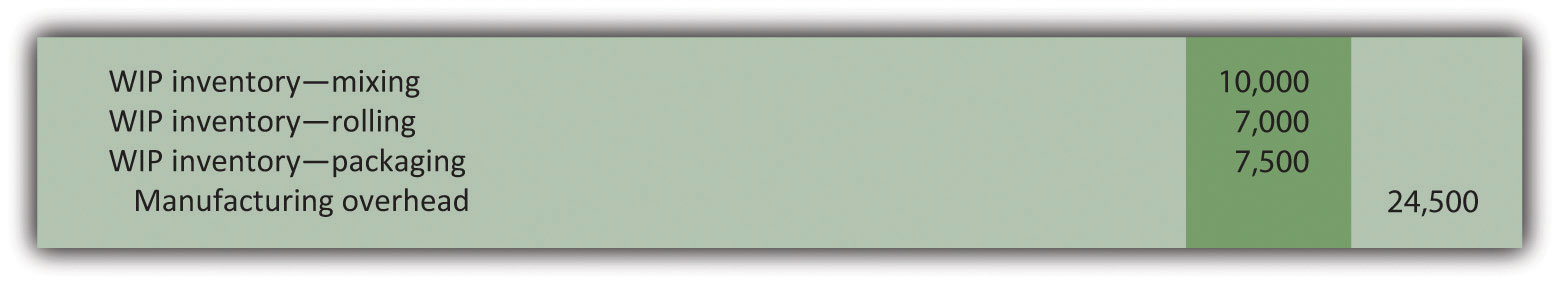

Manufacturing overhead costs are applied to each department as follows:

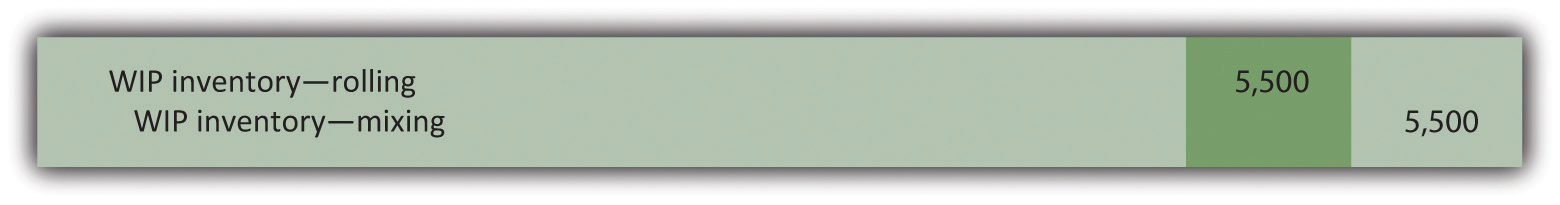

Mixing $10,000 Rolling $ 7,000 Packaging $ 7,500 - Products with a cost of $5,500 are transferred from the Mixing department to the Rolling department.

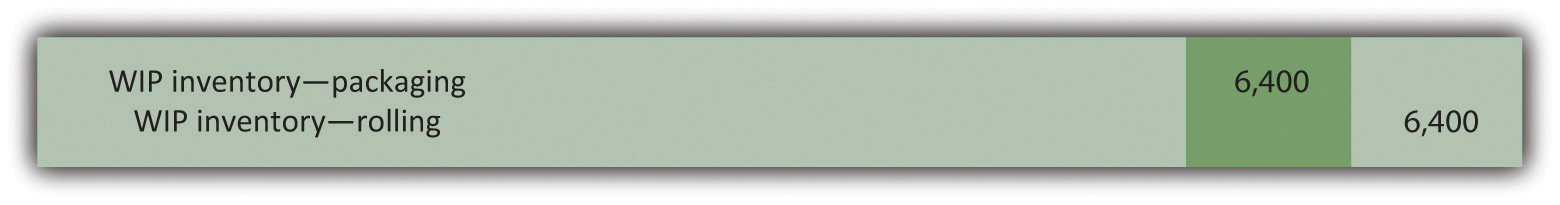

- Products with a cost of $6,400 are transferred from the Rolling department to the Packaging department.

- Products with a cost of $9,100 are completed and transferred from the Packaging department to the finished goods warehouse.

- Products with a cost of $8,300 are sold to customers.

Perform the following steps for each transaction:

- Prepare a journal entry to record the transaction.

- Summarize the flow of costs through T-accounts. Use the format presented in Figure 4.2 "Flow of Product Costs in a Process Costing System" (no need to include T-accounts for raw materials inventory, wages payable, or manufacturing overhead). Assume there are no beginning balances in the work-in-process inventory, finished goods inventory, and cost of goods sold accounts.

Solution to Review Problem 4.2